How Much Does It Cost to Balance a Driveshaft?

Last Updated on June 8, 2024

Written by CPA Alec Pow | Content Reviewed by ![]() CFA Alexander Popinker

CFA Alexander Popinker

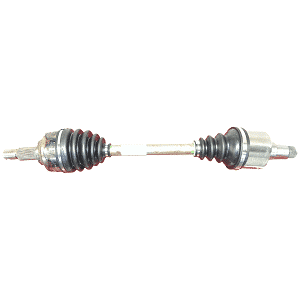

On rear-wheel drive vehicles, the driveshaft is a critical drivetrain component that transfers power from the transmission to the differential, allowing the wheels to propel the car forward. When a driveshaft is out of balance, it can cause annoying vibration, shaking, and drivability issues. So what’s the typical cost for balancing a driveshaft to remedy these problems?

This in-depth guide provides a detailed breakdown of driveshaft balancing costs, including parts pricing, labor rates, variables that impact pricing, and tips to find reputable mechanics and save money. Read on to learn everything consumers should know about budgeting for smooth and safe driveshaft balancing.

How Much Does It Cost to Balance a Driveshaft?

Expect to pay anywhere from $100 to $400+ for parts and professional labor to properly balance your driveshaft, depending on the make, model, and type of vehicle.

For a basic driveshaft balancing job, common repair costs typically include:

Parts – $20 to $200

- Precision balancing weights – $10 to $30

- Potential U-joint or driveshaft component replacement – $20 to $200

Professional Labor – $70 to $300

- Shop hourly labor rate – $70 to $150 per hour on average

- Total job time – 1 to 2 hours for most vehicles

- Labor fees – $70 to $300

Additional Charges – $50 to $150

- Diagnostic testing fee – $50 to $100

- Alignment check or adjustment – $50 to $150

- Taxes, shop supplies, disposal fees – $20 to $50

Total Driveshaft Balancing Cost – $100 to $400+

Larger trucks with heavy duty drive shafts typically fall at the upper end of the price range.

According to Vintage Mustang Forums, the cost of driveshaft balancing can range from around $75 to $150, with some shops charging higher rates for specialized services.

Ford Truck Enthusiasts Forums reports that the cost of driveshaft balancing can range from $130 to $175, depending on the level of service required. For example, a complete rebuild with new U-joints and balancing can cost around $175.

StangNet mentions that the cost of driveshaft balancing can range from $120 to $170, depending on the level of service and the type of U-joints used. Bimmerforums provides insights into the cost of driveshaft balancing in the 1980s, stating that it used to cost around $25 in Santa Cruz county. Today, the cost is likely to be higher, with estimates ranging from $50 to $75 for a standard balancing service.

Bimmerforums provides insights into the cost of driveshaft balancing in the 1980s, stating that it used to cost around $25 in Santa Cruz county. Today, the cost is likely to be higher, with estimates ranging from $50 to $75 for a standard balancing service.

What is Involved in Balancing a Driveshaft?

Balancing a driveshaft is a multi-step process performed by certified mechanics to diagnose and correct any imbalances causing vibration or shaking issues:

- The driveshaft must first be disconnected and mounted on a professional balancing machine.

- The balancer spins the shaft at high speeds and calculates the precise locations and amounts of counterweights needed.

- Small balancing weights are affixed at strategic points along the shaft to offset inherent heavy spots causing imbalance.

- The driveshaft is precision spin tested again to verify perfect balance has been achieved.

- Worn U-joints or damaged driveshaft components may also need replacement in the process.

Proper driveshaft balancing is crucial for optimal drivability, handling, performance, and longevity of the driveshaft and related components.

Factors Impacting the Cost of Driveshaft Balancing

Several variables affect the total pricing to balance a driveshaft for an individual vehicle:

- Type and size of vehicle – Trucks with larger shafts cost more than a compact sedan.

- Extent of the driveshaft imbalance – More weights and tuning precision costs extra.

- Labor rates at the repair shop based on location, reputation, overhead.

- Replacement parts needed – U-joints, center bearings, slip yoke can add costs quickly.

- Additional repairs required alongside – wheel alignment, suspension, axle work.

- Availability of warranty or coupon discounts to reduce out-of-pocket expense.

Getting written quotes from a few reputable mechanics and shops allows cost comparison. Choose the best value.

DIY Cost Savings vs Risks

You might also like our articles about the cost of replacement of the serpentine belt, the valve cover gasket, or differential repair.

For DIYers with automotive skills, balancing driveshafts at home is possible but challenging:

Potential DIY cost savings:

- Avoid shop labor fees of $70 to $300.

- Buy parts at lower retail prices compared to marked-up shop rates.

Equipment and skill required:

- Professional dynamic spin balancer ($300-$500 for cheap models).

- Mechanical competency in disassembling drivetrain components properly.

- Understanding of proper balance weight amounts and positioning.

Risks and challenges:

- Incorrect balancing leads to rapid vibration recurrence.

- Errors risk damaging the drivetrain through imbalance vibrations.

- No warranty recourse if replacement parts fail prematurely.

Except for the most experienced home mechanics, professional driveshaft balancing is strongly advised to avoid DIY headaches or safety issues.

Symptoms of Driveshaft Imbalance

Watch for these warning signs of driveshaft imbalance when driving:

Watch for these warning signs of driveshaft imbalance when driving:

- Strong vibration or shaking sensations felt in car, especially at certain speeds

- Clunking noises or loud whining sounds from under the car

- Uneven tire tread wear noticed during rotation or replacement

- Car persistently pulls or drifts to one side, difficulty steering straight

Addressing these imbalance symptoms promptly through professional balancing prevents further drivetrain damage long-term.

Warranty and Insurance

In most cases, driveshaft balancing and repairs are not covered by auto insurance or warranties:

- Car insurance only covers accident repairs, not maintenance issues.

- Factory powertrain warranties expire within 5 years or 60,000 miles before most balancing is needed.

- Extended repair warranties may offset the cost if still active, review policy details.

Unless you have a third-party repair warranty, driveshaft balancing costs are typically your responsibility as routine maintenance for out-of-warranty vehicles.

Frequently Asked Questions

Get quick answers to some additional common questions about driveshaft balancing:

How often should you get a driveshaft balanced?

Every 2-3 years or 15,000-30,000 miles is recommended for most driving conditions to maintain smooth operation.

Is it safe to drive with an out-of-balance driveshaft?

Minimal short trips may be tolerated but vibration rapidly worsens. Extended driving risks damaging drivetrain components.

What typically happens if an unbalanced shaft is ignored?

Vibration increases causing wear on tires, bearings, suspensions, U-joints and eventually the driveshaft itself will need replacement.

How long does it take a shop to balance a driveshaft?

Typically 1-2 hours including disassembly and reinstallation in the vehicle. Additional repairs add time.

Can cracked shafts be balanced or do they require replacement?

If the driveshaft is bent, warped, or cracked, no amount of balancing will fix it. Replacement is required in those cases.

Leave a Reply

Want to join the discussion?Feel free to contribute!