How Much Does Flywheel Replacement Cost?

Last Updated on March 14, 2024

Written by CPA Alec Pow | Content Reviewed by ![]() CFA Alexander Popinker

CFA Alexander Popinker

Getting your vehicle’s flywheel replaced can be an unexpected and potentially costly repair. Understanding the factors that influence the price, and finding the right mechanic, are key to getting quality service without overpaying.

This article will break down everything you need to know about flywheel replacement costs.

The flywheel is a crucial transmission component that connects the engine to the gearbox. It’s basically a spinning disc that helps smoothly transfer power to the transmission and drivetrain.

Over time, the flywheel can become damaged or worn out, resulting in transmission slippage or difficulty shifting gears. Replacing a faulty flywheel helps restore proper performance and drivability.

How Much Does Flywheel Replacement Cost?

The average cost to replace a flywheel ranges from $400 to $1,000, including parts and labor. However, prices ultimately depend on:

- The vehicle make and model – The specific design affects the repair difficulty and parts cost. Luxury brands tend to be more expensive.

- Flywheel type – Dual-mass flywheels cost more than single mass. Ceramic models are pricier than steel.

- Automatic transmission vs manual transmission – Manual transmissions have simpler flywheel designs that cost less to replace.

- Mechanic’s labor rate – Prices range from $80 to $150+ per hour based on experience and location.

- Additional repairs needed – Like replacing a worn clutch that requires flywheel removal anyway.

According to CarParts.com, aftermarket flywheel replacements range from $60 to $1,500. The wide price range is influenced by the material, recommended use, brand, and inclusions of the flywheel. The cost of labor for replacing the flywheel may range from $400 to $500, depending on local rates.

Motor Verso notes that the cost of flywheel replacement ranges from $400 to $1,300, depending on the mechanic, location, and the make/model of the car. The average cost is anywhere between $600 to $1,100, including parts and labor.

Electronics Hub writes that the cost of replacing a clutch and flywheel can range from $800 to $1,600 or more, including the part itself and labor. The labor costs typically range from $400 to $800 or more, depending on the complexity of the job and hourly rates.

According to ClickMechanic, the average cost of replacing a flywheel and clutch is £875, with prices ranging from £650 to £1,200. The exact price depends largely on the car and its parts.

How a Flywheel Works in Your Car

Before getting into the details on replacement costs, let’s first review what the flywheel does:

- It’s mounted to the crankshaft, spinning along with engine RPMs.

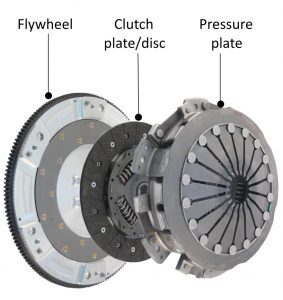

- A clutch disc connects the flywheel to the transmission input shaft.

- When the clutch is engaged, the flywheel spins the transmission. When disengaged, it disconnects the engine from the drivetrain.

- It evens out power delivery thanks to its weight, helping smooth gear shifts.

- Over time, heat and friction can cause surface cracks or runout (imbalance).

Replacing a damaged flywheel helps ensure proper clutch function and transmission performance.

Factors That Impact the Cost of Replacement

Several variables affect what you’ll pay for flywheel replacement:

The Vehicle Make and Model

The specific car design dictates the labor hours and parts cost:

- Accessibility impacts repair difficulty and book time. Rear-wheel drive is often easier than front.

- Luxury and high-performance cars use heavy dual-mass flywheels that cost more.

- OEM parts for imports like BMW or Audi are pricier than domestics.

Type of Flywheel

Flywheel design affects the parts cost:

- Single mass flywheels are simpler and cheaper, found on many manual transmissions.

- Dual-mass flywheels are heavier duty for smoothness, costing around $350 to $700.

- Exotic ceramic flywheels can cost $1,000 or more but are lighter and more durable.

You can also check out our articles about the replacement of the idler arm, tires, heater core, and brake pads.

Transmission Type

Manual transmissions have simpler, cheaper flywheels:

- The flywheel is bolted directly to the crank. Easy removal cuts labor time versus automatics.

- Materials are often steel instead of heavy dual-mass designs. Parts cost less.

- Clutch kits with a new disc are around $400 to $900 in total.

Mechanic Labor Rates

Shop rates typically range from $80 to $150 per hour:

- Independents and general repair shops charge less than dealerships.

- Experience level also affects rates. Master technicians command higher hourly fees.

- Location factors in too. Major metro areas have higher labor rates.

Additional Repairs

Combining the flywheel job with other repairs saves money:

- Clutch replacement is recommended when replacing a manual transmission’s flywheel. This avoids labor duplication since the transmission has to be removed for both. Clutch kit cost can add $400 to $900 in parts.

- Rear main seal, pilot bearing, or transmission service may also be advised since the transmission is already opened up.

Choosing a Reputable Mechanic or Repair Shop

Selecting the right automotive service center ensures quality workmanship when getting your flywheel replaced:

- Dealerships employ specialist technicians and use OEM parts, but have higher shop rates. A good option for newer vehicles under warranty.

- Independent shops offer greater affordability, expertise working on various makes/models, and quality non-OEM parts sourcing.

- Online reviews, certification/accreditations, and word-of-mouth references help identify reputable mechanics.

- Get multiple repair quotes to compare pricing and services recommended.

- Look for a shop that provides warranties on parts and labor.

What’s Involved in Replacing a Bad Flywheel?

Here are the general steps performed by the mechanic during flywheel replacement:

- Drain transmission fluid and detach the driveshaft. Support transmission with a jack.

- Remove transmission bolts and disconnect the shift linkage. Carefully pull the transmission back.

- Detach clutch components to access the flywheel. Mark flywheel orientation for proper reinstallation.

- Remove flywheel bolts and detach from the crankshaft flange. Check the rear main seal, pilot bearing, etc.

- Install new flywheel, torque converter, and torque bolts to OEM specs. Reinstall the clutch and transmission.

- Refill transmission fluid. Road test car to verify smooth shifting and clutch operation.

The full repair takes 4-6 hours for rear-wheel drive vehicles. The front-wheel drive can add 1-2 hours.

Flywheel Quality and Types

Flywheel construction affects durability, drivability, and cost:

Flywheel construction affects durability, drivability, and cost:

- Single mass steel flywheels are affordable but transmit more vibration. Used on most manual transmissions.

- Dual-mass flywheels are heavier duty, using springs and dampers to reduce vibration. Cost more but smoother.

- Ceramic flywheels are extremely light and durable. Offer the best performance but are very expensive.

Pricier flywheels often provide better drivability and longer service life. Sticking with OEM specifications is recommended, especially on European vehicles.

Labor Fees and Repair Timeframes

The shop rate and book time set the labor cost portion:

- The shop rate (hourly labor fee) typically ranges from $80 to $150 based on location and mechanic skill level. Dealers tend to be higher.

- Book time (set hours for the repair) is 4-6 hours for RWD cars, up to 8 hours for FWD. This accounts for full transmission removal.

- At a $100 per hour rate over a 5-hour book time, labor costs would be around $500. Parts are extra.

Most shops can complete the full replacement in a single day or within 24 hours. Vehicles can be difficult to shift prior to repair but are drivable.

Potential Additional Maintenance or Repairs

When the transmission is open for flywheel service, some additional repairs may be recommended:

- Clutch replacement is often advised, adding $400-$900 in parts for a new disc, pressure plate, throwout bearing, etc.

- Replacing worn parts like the rear main seal, pilot bearing, or transmission mount can prevent future leaks or failure.

- A transmission fluid change or flush ensures fresh, clean fluid is used after reassembly.

- Consider a full transmission tune-up if your vehicle has high mileage. This provides comprehensive service.

Doing these repairs together reduces duplication of labor costs down the road. Discuss options with your mechanic during the quote process.

Final Words on Flywheel Replacement Cost

While actual flywheel replacement costs vary based on your vehicle and shop, the average is around $900 in total parts and labor. Get quotes from multiple trusted mechanics to find the best value.

Look for a shop that provides a warranty and uses quality parts. Combined repairs like a clutch replacement can optimize the value of the major service. Your vehicle’s transmission will operate like new again after getting the flywheel replaced.

Frequently Asked Questions

Is it worth replacing a flywheel?

Yes, replacing a damaged or faulty flywheel is worth the repair cost. The flywheel is a vital mechanical component that enables smooth engine operation and gear shifts.

Replacing a cracked or warped flywheel restores proper clutch function and drivability. It also prevents further damage to the transmission system.

Can you drive with a bad flywheel?

It’s not recommended to continue driving with a malfunctioning flywheel. While the vehicle may still operate, you may experience transmission slippage or difficulty shifting.

A bad flywheel can lead to accelerated wear on the clutch and transmission components. Driving should be limited to short trips to the repair shop before replacement or at least resurfacing. Some cars even need a new clutch.

Can a bad flywheel damage the gearbox?

Yes, a damaged flywheel can potentially damage the transmission gearbox. The flywheel is mounted directly to the gearbox input shaft. If the flywheel is cracked or warped, it will wobble and put abnormal stress on the transmission, resulting in premature wear of the gears and release bearings.

Small metal fragments can also break loose and circulate through the transmission fluid, causing grinding. Getting the faulty flywheel replaced promptly helps prevent these gearbox failures down the road.

I didn’t know that slipping of the gears is a sign of a bad fly wheel. That sounds like what is happening to my car. Maybe I can get it looked at and repaired if needed.