How Much Does Acetylene Tank Refill Cost?

Last Updated on February 28, 2024

Written by CPA Alec Pow | Content Reviewed by ![]() CFA Alexander Popinker

CFA Alexander Popinker

Acetylene is an essential gas used for many industrial applications, especially welding and metal fabrication. Understanding the costs associated with acetylene refills is crucial for properly budgeting projects and optimizing operations.

This article will provide an overview of the key factors influencing acetylene refill pricing, tips for cost management, and resources to help find the most affordable suppliers.

How Much Does Acetylene Tank Refill Cost?

Acetylene refill pricing can vary quite a bit based on several factors, but here is more detail on cost ranges to expect:

Small 5-15 cu ft portable tanks – These smaller cylinders are commonly used for light-duty welding by hobbyists, DIY, and mobile applications. Refilling tanks this size typically range from $25-60 per refill.

Factors like purchasing a single refill on-demand vs getting a multi-refill package deal can affect per-unit costs. Exchanging an empty for a full tank can cost between $30-45 from suppliers like local welding shops that offer exchange programs. Overall, the budget is $40-75 per refill for standard portable acetylene tank sizes.

15 cu ft standard tanks – The most common tank size seen at many welding shops, garages, and fabrication shops. Refilling 15 cu ft cylinders runs between $35-90 per tank. Buying multi-tank refill packages can save 10-15% compared to single fill-ups. Exchanges may cost $50-70 per swap. Budget around $60-100 per 15 cu ft tank refill under average conditions.

125 cu ft larger tanks – For heavy commercial and industrial usage, larger 125+ cu ft tanks are preferred to get bulk rates. However, an initial investment in cylinders this big can be $1,000+ new.

Refilling these tanks starts around $100-250 per refill depending on quantity and market rates. exchanges may run $150-225 each through gas suppliers. Plan for $150-300 per refill for high-volume 125 cu ft tanks.

Bulk refills (500+ cu ft) – For major industrial consumers, bulk acetylene purchases via large ASME tanks over 500 cu ft offer the cheapest per unit rates. Buying 500-1000 cu ft at once can secure rates as low as $4-8 per 100 cu ft. Negotiating bulk contracts around $5-10 per 100 cf provides optimal pricing but higher initial buy-in costs.

Regional factors like higher urban demand can add 10-40% to costs, while rural areas may be priced below these ranges. Carefully vetting suppliers, comparing rates, and negotiating contracts for large volumes are key tactics to get the lowest acetylene refill costs.

But in general, budgeting $6-12 per 100 cf covers average acetylene refill expenditures for most shops and operations.

A WeldingWeb Forum discussion revealed that in Indiana, at a local Airgas, the MC-sized Acetylene and oxygen tanks together cost $79.78 to refill. The B tank sized Oxygen tank costs $56.80, and a similar price applies to the Acetylene tank, which is $56.80 for each tank.

On Toll Gas & Welding Supply the cost of an Acetylene refill ranges from $33.86 to $407.00. This price includes the cylinder, gas, and associated fees. The purchased cylinder comes with a valid DOT stamp, current hydrostatic test stamp, and a record of ownership.

FaucetDepot.com offers a B Tank Acetylene Refill at a retail price of $91.92, but their price is discounted to $55.42. Additionally, they provide free shipping on orders over $199.

Applications of Acetylene Gas

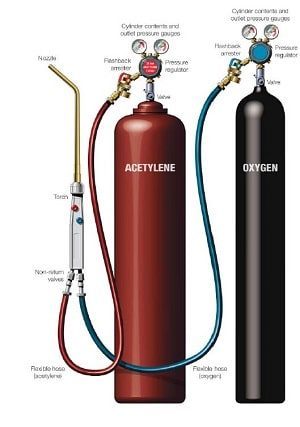

Acetylene’s high flammability and wide range of burning temperatures make it ideal for metal welding and cutting applications. The gas is commonly used in oxy-acetylene torches, which mix acetylene with oxygen to produce a hot flame exceeding 3300°C.

This allows the gas to be used for welding, brazing, soldering, and thermal cutting of various metals.

Beyond welding, acetylene also has applications in chemical synthesis, metalworking, and lighting. Its versatility ensures steady demand across many industries. However, continuous use requires having acetylene tanks refilled regularly from suppliers.

Factors That Influence Acetylene Refill Costs

Several factors impact the pricing for acetylene tank refills:

- Tank size – Larger tank sizes can benefit from bulk pricing discounts. 15 cu ft tanks are common for portable use, while 125+ cu ft tanks offer more gas capacity for heavy commercial use. Larger tanks will have a lower per cubic foot refill cost.

- Refill quantity – The amount of gas refilled each time can affect pricing. Acetylene is typically measured in cubic feet (cf). Bulk refills offer lower per cf rates.

- Suppliers and supply model – Industrial gas suppliers, local welding shops, and nationwide chains have varying acetylene refill rates. Pricing also differs between tank exchange models vs cylinder refills.

- Location/Region – Geographic factors like demand, supply logistics, and competitiveness between suppliers can impact local market prices.

- Purity grades – Higher purity grade acetylene for special applications can cost 20-50% more than standard industrial grades.

- Safety and service fees – Some suppliers bundle in testing, maintenance, rental fees, etc. that add to the base gas price.

- Market conditions – Acetylene pricing is affected by raw material costs, fuel prices related to transport, seasonal demand shifts, and competitive forces.

Finding Reliable Acetylene Suppliers for Refills

It pays to research options and find reputable, affordable acetylene suppliers in your region. Here are some potential sources to check:

It pays to research options and find reputable, affordable acetylene suppliers in your region. Here are some potential sources to check:

- Local welding supply stores – Many small businesses offer on-site refills or exchanges. Check for longevity, community reputation, and competitive rates.

- Industrial gas companies – National chains like Airgas, Air Liquide, Matheson, or Praxair have established supply infrastructure and bulk capabilities but may charge premium prices.

- Welder trade groups – Organizations like the American Welding Society provide supplier directories and support finding local options.

- Gas cylinder exchanges – Programs like Linde Gas allow exchanging empty tanks for full ones at predictable nationwide rates.

- Online welding forums – Discuss supplier recommendations with other welders and fabricators in your area through communities like WeldingWeb or Reddit.

Prioritize certified, licensed suppliers adhering to necessary safety standards for compressed gas. Review pricing lists, factor in rental fees or extra charges, and compare rates across several options before choosing regular refill services.

Financial Tips

Here are some tips to help optimize acetylene expenses over the long run:

- Use acetylene efficiently – Prevent waste by calibrating torches, matching nozzle sizes to need, and avoiding leaks.

- Purchase larger tanks – Larger cylinders have lower per cf refill costs. Invest in a 125+ cu ft tank if usage justifies it.

- Refill before completely empty – Allowing tanks to fully empty triggers more extensive refill preparation adding fees.

- Buy in bulk – Negotiate bulk gas purchase contracts for large, predictable volumes at discounted rates.

- Leverage promotions – Take advantage of seasonal discounts, loyalty programs, and coupons when available. Sign up for refill reminders/specials.

- Compare pricing – Regularly check market rates and compare supplier quotes to find the best deals.

- Consider rental vs. purchase – If usage is sporadic, renting cylinders as needed avoids ownership costs.

- Share tanks – Arrange tank rentals/access with other nearby welders, when possible, to split costs.

Proper acetylene tank refill planning, usage monitoring, and cost management can yield significant long-term savings on one of the welding’s biggest consumable expenses.

Related Resources for Safe, Affordable Acetylene

Besides suppliers, there are other helpful resources related to managing acetylene expenses:

Also read about the costs of water leak fixing, roto rooter plumbing, and locksmith services.

- Safety groups like the Compressed Gas Association provide cylinder handling/storage guidance to prevent cost escalations from accidents.

- Trade schools offer training in efficient welding techniques to minimize waste.

- Industrial gas apps like AirLiquide’s Weldeye help track gas usage and spending.

- Price aggregators like QuickGas and GasPriceWatch allow price comparisons between local suppliers.

- Cylinder exchanges like Airgas’ Ready-Pak program provide fixed-cost refill convenience.

- Bulk gas buyers co-ops can negotiate collective discounts on acetylene purchases.

- Cylinder testing through hydrostatic retesting providers allows safe extended tank use instead of costly replacements.

Tapping into these resources supplements a strategy of selecting the most affordable suppliers while ensuring proper handling for safety and cost control.

Final Words

With acetylene being a major consumable for industrial applications, keeping refill costs in check should be part of any operational budget. Compare market rates to target the most affordable local suppliers.

Optimize usage, buy in bulk when possible, and employ promotions or programs that offer discounts. Monitor expenses over time and adjust purchasing strategies accordingly.

With some research and planning, acetylene refills can become a well-managed line item instead of a fluctuating production cost. Evaluating options against your usage needs will help strike the ideal balance of safety, convenience, and affordability.

Frequently Asked Questions

What is the 1:7 rule for acetylene?

The 1:7 rule refers to the proper ratio for acetylene storage. Acetylene cylinders should only be filled to 1/7 of their total capacity, i.e., 14.3%. This prevents risks associated with acetylene becoming unstable under pressure. Exceeding 14.3% capacity in storage tanks can create explosion hazards.

What are the rules for storing acetylene cylinders?

Key rules for safely storing acetylene include:

- Cylinders must be upright and secured firmly to prevent tipping/falling.

- Storage areas should be cool, dry, well-ventilated, and away from heat/flame sources.

- Full and empty cylinders should be stored separately.

- Avoid storing acetylene near oxygen or other oxidizers.

- Clearly label/mark tanks and position valves for quick access if needed.

- Limit storage quantities based on facility size and fire codes.

How do I know when my acetylene tank is empty?

Signs your acetylene cylinder is empty or nearly depleted include:

- The pressure gauge shows zero psi.

- The tank feels much lighter in weight when lifted.

- Torch flame burns lower/goes out as the gas flow drops.

- A whistling/sucking sound comes from the regulator/torch as the remaining gas gets drawn out.

- Acetylene discharge rate/pressure from tank decreases despite valving being fully open.

Always keep a spare cylinder on hand to swap out promptly when the active tank runs empty. Never use a cylinder believed to be entirely devoid of acetylene.

At what temperature does acetylene become unstable?

Acetylene can become unstable at elevated temperatures, presenting an explosion hazard. At around 305°F/152°C, acetylene gas inside a pressurized cylinder can spontaneously detonate without warning. S

toring cylinders where temperatures exceed 125°F/52°C should be avoided. Using acetylene at high pressures also promotes instability, making the 305°F autoignition point considerably lower under pressure.

Leave a Reply

Want to join the discussion?Feel free to contribute!