How Much Do Railroad Ties Cost?

Last Updated on June 18, 2024

Written by CPA Alec Pow | Content Reviewed by ![]() CFA Alexander Popinker

CFA Alexander Popinker

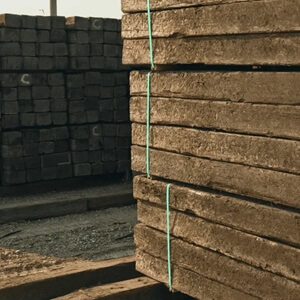

Railroad ties, also known as railway sleepers or crossties, are a critical structural component of train tracks, providing the foundation, stability, gauge spacing, and weight distribution needed for trains to smoothly travel down tracks. Railroad ties are usually constructed from durable rot-resistant hardwoods like white oak, black locust, or pressure-treated softwoods, then preserved with creosote or copper azole preservative solutions to resist decay and extend service life.

When sourcing new or used railroad ties for commercial construction projects, residential landscaping designs, garden railroads, retaining walls, as organic garden borders, steps, and heavy duty structural applications, the per-tie cost is an important consideration during project planning and budgeting stages.

This guide covers everything – from where to source new and used ties, to how wood species, size, and treatment impact durability and pricing, to bulk purchasing strategies that maximize value on large railroad tie orders. Let’s examine current railroad tie costs in detail.

How Much Do Railroad Ties Cost?

On average, expect to pay between $15 to $40 per standard new or good quality used tie in common sizes. However, railroad tie pricing can range from as low as $5 for old used cracked ties being liquidated up to $150 or more for the largest, premium new oak or concrete ties used on high-traffic mainline rail tracks.

To illustrate how age, wood type, preservative treatment, size, grade, and purchase quantity factors influence quoted per-tie rates, here are typical current retail costs based on those specifications:

Used/Reclaimed Railroad Ties

- Old cracked ties being liquidated, limited usable life left – $5 – $15 per tie

- Good condition used ties with 10+ years of service life remaining – $15 – $25 per tie

New Railroad Ties

- Basic untreated pine, fir or cedar ties – $15 – $30 per tie

- Mid-grade hardwood ties made from mixed oak, maple, etc. – $25 – $35 per tie

- Premium treated white oak and black locust ties – $35 – $60 per tie

- Heavy duty mainline oak ties, creosote treated – $80 – $150+ per tie

- Concrete ties for specialty track sections – $200 – $350 per tie

Other Railroad Tie Pricing Aspects

- Free delivery included for bulk full truckload tie orders. Partial pallet delivery typically adds a $50 – $200 fee based on location.

- Major railroads charge suppliers for used tie removal, impacting used tie costs.

- Sales tax applies to new ties. Used and reclaimed ties are tax exempt.

- Shipping costs per tie on extremely heavy ties means buying within ~100 miles of suppliers is ideal unless you can order full railcars.

Kurtz Bros. offers railroad ties at a price of $26.75 per unit, with quantity discounts available. The website highlights that the ties are sold online in bundles only, but can be purchased individually in stores.

Used Railroad Ties in Western US provides a range of prices for used railroad ties, with Grade #1 ties selling for $28.00 each, Grade #2 ties selling for $20.00 each, and Grade #3 ties selling for $20.00 each. The website also offers large beams at a price of $225.00 each, with discounts available for bulk purchases.

Factors Influencing Railroad Tie Pricing

Several important considerations influence the per-tie pricing quoted by suppliers for railroad ties based on their attributes:

- New vs. Used/Reclaimed – Brand new railroad ties are typically 2 to 3 times more costly per tie than used and reclaimed railroad ties sourced from decommissioned rail lines or tie replacement projects. Savings of 50% or more off new tie costs are common when substituting good quality used ties on projects where codes permit it.

- Wood Species and Grade – Naturally rot-resistant species like white oak, black locust, red mulberry and tropical hardwoods command higher prices given their 25+ year lifespan. Softwoods like pine, fir, or cedar cost less initially but require replacing twice as often.

- Preservative Chemical Treatment – Ties pressure-treated by soaking in creosote, copper azole or other preservative solutions add 10-30% to cost but drastically extend usable lifespan. Mainline ties are commonly creosote treated.

- Size, Length and Weight Rating – The largest, heaviest duty ties rated for use on high-traffic mainline rail tracks understandably demand higher per-tie prices from suppliers than common standard ties used for rail sidings, yards, and spur lines. Custom extra-long ties also cost more.

- Purchase Quantity – Bulk tie buyers can realize volume discount savings of 20-30% off standard retail per-tie rates when purchasing in full truckload or railcar quantities from wholesale sawmills or larger tie distributors compared to picking up partial pallets from local sellers.

When sourcing railroad ties, new white oak ties bought in volume from regional tie distributors will provide an ideal balance of durability, strength, and reasonable lifetime per-tie cost for most residential and commercial heavy duty structural installations. Used ties offer budget-conscious savings for smaller scale projects where codes permit it.

You might also like our articles on the cost of wood retaining walls, wood piling, or mahogany wood.

Where To Source Affordable Railroad Ties

For best pricing on used railroad ties with cost savings of 50-75% or more compared to new tie costs, check these bulk suppliers:

- Railroad salvage companies – Miles of abandoned rail lines are demolished annually. Companies specializing in acquiring used ties from these projects sell bulk quantities. Quality varies so inspect before committing.

- Rail contractors – Companies contracted for tie replacement programs receive the used ties removed, which they sell in bulk. Again, inspect and hand select ties onsite if possible.

- Habitat for Humanity ReStores – Some locations acquire used railroad ties periodically from local demolition projects and sell to the public at reasonable bulk pricing. Call local stores.

- Classified listings websites – Search for “rr ties” or “railroad ties” on Craigslist, Facebook Marketplace, etc. Tie removal contractors may advertise large batches of used ties available in your region.

The most important aspect when buying reclaimed ties is setting realistic expectations on lifespan and thoroughly inspecting to screen for defects, rotting, splitting and suitability for the intended application. But huge cost savings are possible on centenarian oak ties removed from a rail line during upgrade projects. These ties can still have decades of service left with the right project fit.

Wood Species and Treatment

The specific wood type and preservative treatment chemicals used significantly influence expected lifespan and thus value:

White Oak – Very rot resistant wood containing tannins, understood as the premium species for ties. But costs $35 to $60 per tie. Typically lasts 30 to 50 year when well maintained.

Black Locust – Another naturally decay-resistant hardwood containing resistant heartwood. $25 to $40 per tie. Usually lasts 25 to 40 years.

Douglas Fir/Southern Yellow Pine – Affordable common softwoods costing $15 to $30 per tie but have a typical lifespan of just 10-15 years before replacement needed.

Tropical Hardwoods – Ipe, cumaru, jarrah, and other dense imported rainforest woods all resist insects, moisture, and decay. However these ties run $60 to $100+ per tie and raise environmental concerns. Lifespans of 50+ years are common though in ideal conditions.

Preservative Chemical Treatments

- Creosote-treated ties are most effective for 30+ year lifespans but toxicity limits residential usage now. Primarily used for high-volume mainline ties.

- Copper azole and other preservative solutions are safer and commonly specified for yard ties, industrial projects, landscaping, and commercial applications needing decay resistance.

While white oak is considered the gold standard, even properly treated pine ties can still last 15-20 years in moderate duty applications. Consider lifespan, location, and budget when selecting railroad tie species.

Bulk Purchase Strategies

Capitalizing on volume discounts for massive tie supply needs on large scale commercial projects or expansive residential landscaping installations requiring 500+ ties can yield dramatic per-tie savings:

Capitalizing on volume discounts for massive tie supply needs on large scale commercial projects or expansive residential landscaping installations requiring 500+ ties can yield dramatic per-tie savings:

- Retail price per tie when buying partial pallets of 25-50 ties – $28 per tie

- Wholesale pallet rate for quantities of 100-500 ties – $22 per tie

- Standard bulk rate for 500-2000 tie purchases – $18 per tie

- Jumbo bulk purchase of 5000+ ties – $12 per tie

Volume discounts up to 60% off individual retail tie rates are possible when buying jumbo quantities for major railroads or contractors. Coordinate group buys in an area to reach higher quantity tiers. Storage space for ties is the limitation.

For smaller residential projects, used ties, même pricing, free delivery thresholds, and cash/check discounts can help trim costs.

Frequently Asked Questions

How long will railroad ties last?

Properly installed oak, black locust, or tropical hardwood ties often last 25-30+ years. Softer woods like pine or fir will need replaced every 10-15 years. Actual longevity depends heavily on climate, weather exposure, maintenance upkeep, and track traffic levels.

Can reclaimed and used railroad ties be reused for residential landscaping projects?

Yes, used ties are very popular for home landscaping, gardens, and retaining walls if still in good structural condition without excessive cracking or rot. Always closely inspect ties onsite before purchase and delivery to ensure satisfactory remaining lifespan. Look carefully for defects. Many century-old ties removed from abandoned lines still have years of service left when repurposed creatively in the right applications.

How are used railroad ties disposed of in an eco-friendly manner?

Reusing ties is the primary goal. If ties are indeed worn out, they can be ground into landscaping mulch, shredded for boiler fuel, repurposed into erosion control, recycled into composite lumber, or as a last resort placed in specially lined landfill cells. Very few ties end up in landfills now as reuse and recycling has increased dramatically to over 50% of ties removed.

Leave a Reply

Want to join the discussion?Feel free to contribute!